MasterControl application integrates CAPA procedures with the whole products life cycle for just a holistic method of excellent and CAPA administration.

What is the magnitude of the situation? Could it be in one analyze, or does the problem exist in all experiments under this PI and even in a whole medical department?

Reactive vs. Proactive: Corrective action is implemented after a nonconformity is claimed. Preventive action is predicting a likely prevalence or recurrence of an issue and mitigating the chance.

Senior personnel should regularly assessment your inner audits, employees consciousness instruction benefits, and insurance policies to check your development toward aims.

7) Check that the plan labored. To put it simply, after you have produced your updates, wait around an appropriate period of time and ensure the trouble doesn’t recur. If it does, you might want to issue if you bought the particular root induce.

Root result in Evaluation that identifies the cause of a discrepancy or deviation, and advise corrective actions

Obstacle the quality info data method. Verify that the information been given via the CAPA technique are entire, accurate and well timed.

Each time a symptom is observed or communicated, a systematic list of things to do are initiated. The pursuits are meant to explain the condition in adequate element so that the staff can establish a root trigger route.

An Preliminary correction could possibly be issued in the shape of the program patch. When the lead to(s) from the bug are established the corporation will situation a long term Answer for your computer software and employ controls within their improvement system to circumvent reoccurrence with the bug.

and blocking the reoccurrence in the weaknesses you’ve determined. In contrast, preventive click here action is proactive and stops

MasterControl CAPA software package digitizes and automates CAPA procedures such as routing, notification, escalation and approvals to stay away from bottlenecks and expedite problem resolution.

2. Ascertain if suitable resources of products and quality troubles happen to be determined. Verify that facts from these sources are analyzed to discover existing products and top quality issues that could involve corrective action.

Liable Person: The name on the responsible person for that completion of the recommendations shall be created get more info in session with the priority department head by QA

Action is taken to reduce the cause of a possible nonconformity, defect or other unwanted scenario, as a way to stop event.

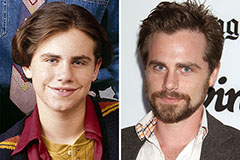

Rider Strong Then & Now!

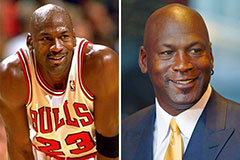

Rider Strong Then & Now! Michael Jordan Then & Now!

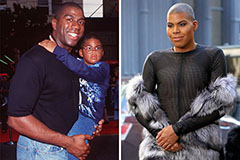

Michael Jordan Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Dolly Parton Then & Now!

Dolly Parton Then & Now! Megyn Kelly Then & Now!

Megyn Kelly Then & Now!